SureCav’s concrete commitment to environmental excellence...

21 November 2019

SureCav’s concrete commitment to environmental excellence...halves carbon footprint of cavities

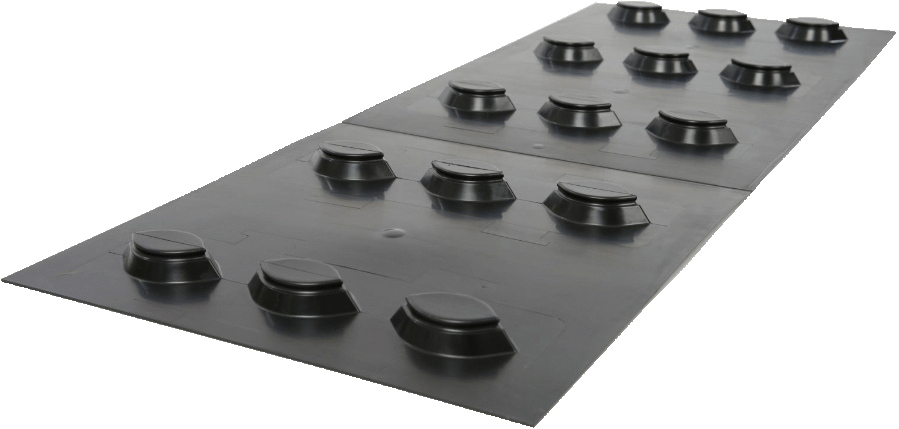

A revolutionary BBA-Certified cavity spacer system that has simplified the construction of natural stone buildings over the last 15 years continues to raise the bar environmentally by almost halving the carbon footprint of a cavity construction when compared to traditional methods.

SureCav creator Charlie Ayers tore up the rule book when he developed the product to replace concrete backing blocks and timber shutters on buildings with an outer skin of natural stone, ensuring clean dry cavities and properties with improved insulation and footprints that are 7.5% larger*.

The patented, award-winning system not only reduces the use of concrete blocks (one ton of SureCav replaces 71 tons of concrete blocks on-site, slashing environmental/road haulage impact), continued investment in product design by Charlie and his team in Wincanton, Somerset, has delivered a 100% recycled polypropylene product which has, to date, replaced the equivalent of 4.2 million concrete blocks on-site.

Integral to this innovation has been SureCav’s relationship with the BBA, which has worked closely with the company to maintain seamless Certifications as product formulations have been amended to encompass greater plastics recycling, as Steve Young, SureCav Design Consultant explained: Our product has evolved over time and the BBA was there for us at every step in the process.

“Obtaining product approval and certification was an essential step in taking SurCav to market. We found BBA accreditation to be readily accepted in the construction industry, from architects and designers at the planning stage, to bricklayers and stonemasons on installation. The BBA assisted with development queries and helped clarify the regulations as new clients saw the potential of using SureCav in their areas of construction,” added Steve.

SureCav gained its first BBA Certification in 2004 for SureCav 50, with SureCav 25 launching with accreditation in 2016. The system is now widely used by volume house-builders throughout the UK.

Wendy Ajuwon, BBA Head of Marketing, said: “SureCav introduced a new injection moulding process in 2011 which enabled it to increase the use of recycled plastics into the manufacturing process. Because the product formulation changed it was necessary for us to work closely with SureCav to ensure it, and our, high standards were maintained and the finished products continued to meet our Certification’s stringent quality and performance assessments.

“SureCav is a great illustration of a company taking its environmental performance really seriously and working with us to ensure that Certification remains in place throughout product research, development and product implementation,” added Wendy.

*for a two-story, three-bedroom house.

See the full article: https://www.bbacerts.co.uk/blog/post/surecavs-concrete-commitment-to-environmental-excellence

.png)