- SureCav 25

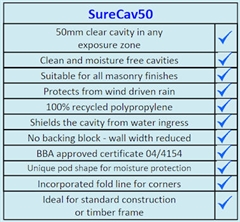

- SureCav 50

- Washers

- Type-W Vent

- Type-W Vent Extender Duct

-

Important: Please check that you have ordered the correct depth of SureCav!

Important: Please check that you have ordered the correct depth of SureCav!

Call Us 01963 34660

Panel size: 1200x450x50.

It is a moulded, 100% recycled, polypropylene panel with spacer protrusions, forming a 50mm clear cavity and providing the perfect backing board for the stone, slate, brick and flint outer leaf. SureCav50 is BBA certificated. This cavity protection system ensures clean and moisture free cavities with either timber frame or traditional construction.

Panel size: 1200mm (L) x 450mm (H) x 50mm deep

Protects envelope of building

Lightweight sheet

Recycled polypropylene

Internal floor area

Fixing: Wall ties are used, as standard, vertically every 450mm mortar course. Helical ties are most useful where additional support is required between courses and can be fixed through the flat face of the sheet.

For timber frame, it is recommended that sealing washers (supplied by SureCav) are screwed into the pods, with or without additional timber frame ties to hold the system in place prior to the construction of the outer masonry leaf.

Use 5 washers per sheet to ensure stability in high winds before the outer leaf is constructed.

Learn more